The pictures as promised in the last post...

those were the first parts we made :)

That one was at 3ezbet el na7'l, at the workshop where we assembled the parts for the first time :)

This is actually one of the happy moments; when you see what you draw and thought about became reality !!!

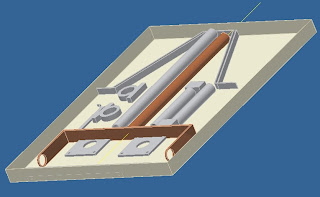

Some close up looks...

Rack-Pinion arrangement;

transferring motion from the linear actuator to the tracker (linear to rotational)

One of the major difficulties that we encountered during the assembly phase of the tracker was that the non-availability of the type of the rotational encoder we planned to use (disk), we had to use another type and the design wasn't made for this one! so we had to improvise.

Trial one

Someone in a different team suggested that design for us. Unfortunately it didn't work as the encoder will not exactly rotate with the same angle as the bearing which is VERY not acceptable as the encoder job IS to measure the angle of the bearing movement :S

Trial two

After several trial and errors, we came up with this design, which is far more accurate and it worked just fine thanks to Allah :)

Final look

That's the final design, after it was polished and the dummy load (glass sheet) was fixed to replace the cells.